The Ball Valve and the Butterfly Valve are two well-known players in the field of industrial valves. These valves, essential parts of many industries, have different functions, each with a unique set of benefits and uses. Let us examine the differences between them to gain a better understanding of their functionalities. Fluton Group is a leading Butterfly and Ball Valve manufacturer in Ahmedabad.

Knowing the Fundamentals

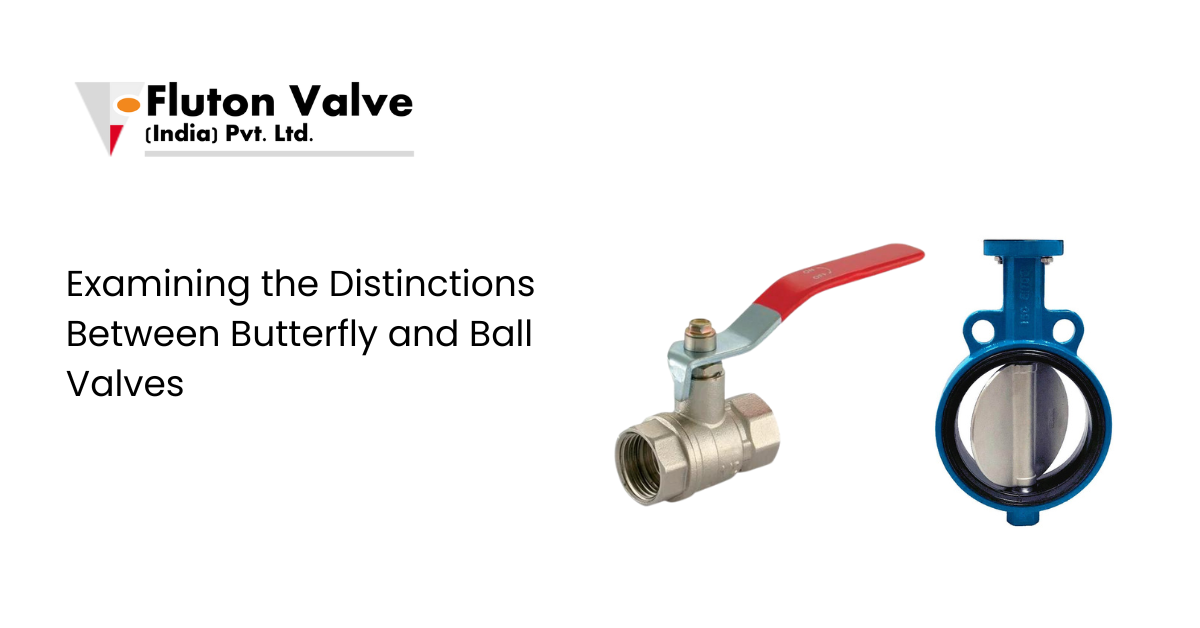

Both butterfly and ball valves are classified as quarter-turn valves because they require a 90-degree turn of the handle or actuator to open or close. Even though they are similar, their internal workings and patterns of operation are very different.

Building and Planning

As the name implies, ball valves have a spherical disc inside. When the valve is open, the ball’s opening corresponds with the flow, permitting the flow to pass through. On the other hand, when the ball is closed, it rotates to stop the flow completely.

Butterfly valves, on the other hand, use a round, flat disc—referred to as the “butterfly”—that is placed in the middle of the pipe. When this disc is opened, it pivots at a right angle to the flow, and when it is closed, it goes back to blocking the flow.

Also read: Different Types Of Ball Valve And Their Pros And Cons

Controlling Flow and Drop in Pressure

Ball valves are perfect for applications where a tight shut-off is essential because of their superior shut-off capabilities. Additionally, its design reduces pressure drops across the valve to guarantee effective flow control.

Because of their design, butterfly valves, although good at regulating modest flows, can show somewhat greater pressure drops than ball valves. But they make up for it with a cheaper and lighter weight, which is useful in some situations.

Uses and Sectors

Numerous industries, such as petrochemicals, pharmaceuticals, water treatment, and others, use both types of valves. Applications needing accurate shut-offs, such as chemical processing facilities and gas pipelines, frequently favor ball valves. However, because they are inexpensive and simple to use, butterfly valves are frequently used in wastewater treatment facilities, water distribution systems, and HVAC systems.

In summary

Although controlling flow is the primary objective of both ball and butterfly valves, their features and designs are tailored to meet distinct needs in diverse sectors. Understanding the differences between these valves is essential in order to choose the best solution for a certain application. Businesses like Fluton Valve, with their dedication to quality and innovation, are able to offer innovative solutions that are customized to fit the changing demands of global industries.