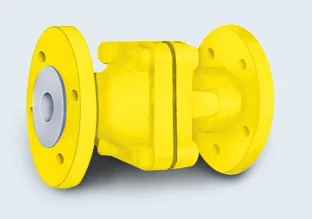

Best Peek Coating in Ahmedabad by Fluton Valve

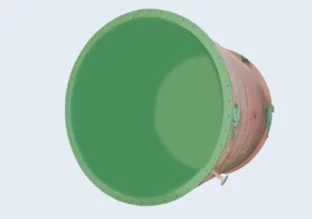

PEEK Coating by Fluton Valve India is a non-toxic and non-flammable material, making it an ideal solution for applications where safety is a top priority. It is a revolutionary, unique, and innovative solution that can be applied to various materials, including metals, plastics, ceramics, and composites.

How are Surfaces and Materials coated with PEEK Coating?

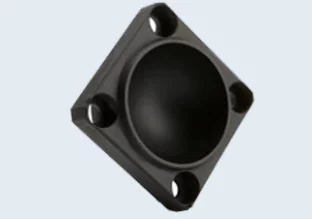

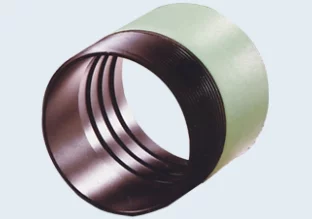

PEEK Coating is a highly effective solution for enhancing the performance and longevity of parts in industries such as aerospace, automotive, electronics, medical devices, and many other industries. PEEK coating is applied in an aqueous or powdered form to the material. Most of the Industrial machinery, wires, and liners have PEEK coatings put on them.

How does PEEK Coating help make materials and surfaces durable?

Heat and chemical exposure are two things that PEEK is quite resistant to. When exposed to Heat and chemicals, it is intact even at temperatures up to 260 °C (500 °F) and resists degradation: It also saves products from:

- Steam, moisture, and water

- Bases, salts, and hydrocarbons

- Electricity

- Biological materials

What Physical Damages can be prevented with PEEK Coatings?

PEEK is resistant to the majority of physical stresses, such as:

- Abrasion

- Galling

- Scratching

- Stress cutting or shearing

- Creeping

- Particulation

- Sloughing

- Crushing

- Tension deformation

- General wear and tear.

Why Collaborate with Fluton Valve for PEEK Coating in Ahmedabad?

At Fluton Valve India, we understand that high-performance components are critical to the success of any application. Our PEEK Coating technology is designed to improve the performance of your components by providing a durable coating that can withstand corrosive chemicals, harsh environments, and extreme temperatures.

How Does PEEK Coating Enhance the Performance and Longevity of Components?

One of the most significant advantages of PEEK Coating is its improved durability, as it provides excellent resistance to wear and tear, abrasion, and corrosion. This means that components treated with PEEK Coating can withstand harsh conditions, extending their lifespan considerably.

PEEK Coating also enhances the performance of components by reducing friction. This leads to better efficiency, lower maintenance costs, and improved product quality. In addition, components treated with PEEK Coating can operate at higher speeds and temperatures without experiencing the usual wear and tear that can lead to costly repairs or replacements.

Contact us today!

At Fluton Valve India, we provide cutting-edge functional coatings and top-notch customer support. The caliber of our work and our tight adherence to deadlines both reflect our commitment to our clients. If you are looking for PEEK Coating in Ahmedabad, Gujarat, contact Fluton Valve India right away for all of your PEEK coating requirements if you want to safeguard your products with PEEK Coating.